Our useful series of articles and case studies on governance of data is designed to give you ideas and examples to better manage your data and use it effectively.

Exception alerting avoids losses

Exception alerting (using tools such as Carbon Desktop’s in-built, real-time alerts) will automatically flag if there is a change from ‘normal’ in your data. Being aware of unusual changes in energy consumption will help you to quickly act on problems and identify areas for continuous improvement, avoiding losses.

Read more in our article:- Exception alerting: What it is and why you need it

Exception alerting case studies

Here are some examples of how exception alerting could help your business to save money:

Case study 1: Operational error correction

One of Verco’s long-term clients utilise exhaust heat from its combined heat and power (CHP) plant to feed a waste heat boiler for steam generation which has a gas top-up feed. In one instance, the waste heat supply was stuck on bypass following an evaporation test, causing the waste heat boiler to reject a large amount of heat requiring a significant amount more gas to provide the steam. This would have resulted in an additional gas spend of £1,000/day.

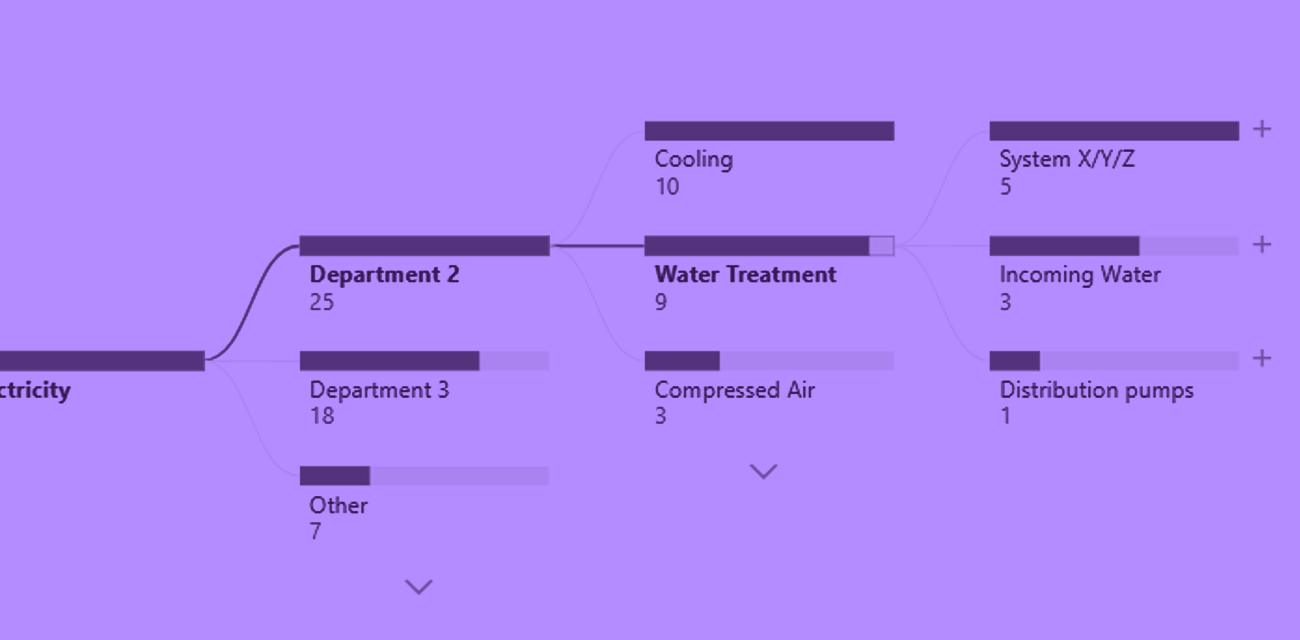

Fortunately, the site monitors CHP exhaust stack temperatures through the Carbon Desktop exception alerting feature. By setting up an exception alert, the unusually high exhaust temperature was flagged (fig 1), allowing the team to investigate and then correct the bypassed valve within a few days. This prevented any further unnecessary gas consumption which would have remained until the next test, saving both costs and carbon emissions. The Carbon Desktop trend below demonstrates the benefits of real-time exception alerting on utility consumption.

Case study 2: Preventing factory stoppages

Verco assisted a client in setting up exception alerts for their air compressor systems, which serve various departments. Historically through energy audits we found that site ran a large fixed air compressor and left their more efficient VSD on standby. This was amended and then through exception alerting we setup alerts for if the fixed compressor ever ran. Months later following an alert sent to site, upon investigation, they discovered that the VSD air compressor had failed, causing the remaining fixed unit to come online and work harder to compensate for the lost capacity.

If this issue had gone unnoticed, it could have severely impacted the site’s ability to meet demand during the busy production season as well as increase energy consumption. Thanks to the timely alert (fig.2), the client was able to quickly address the equipment failure by replacing the malfunctioning compressor, preventing potential production delays and avoiding significant financial losses.

Case study 3: Equipment failure detection

A client of Verco’s had implemented exception alerting on several sub-meters, including monitoring water consumption for their main manufacturing oven. The oven experienced a valve failure which went unnoticed during routine operation. The issue became apparent over the festive period when the production line was shut down, as the oven continued filling with water throughout Christmas and New Year despite no production activity. Fortunately, Carbon Desktop’s exception alerting tool detected the anomaly and promptly alerted the site team, who quickly replaced the faulty valve. By swiftly addressing the issue, the site was able to prevent unnecessary water consumption, saving £500 per day.

Without a real-time alerting system, such issues may go unnoticed for extended periods, particularly during downtime or holidays, compounding the financial impact. By immediately flagging abnormal trends, Carbon Desktop’s exception alerting tool enables site teams to address issues promptly, minimise waste, and prevent substantial losses, ultimately improving operational efficiency.

Contact us if you would like to discuss how Carbon Desktop can help you with data governance here.